TANGSHAN HENGFENG MACHINERY MANUFACTURE CO., LTD.

Booth Number: Hall 4.1 - 4.1D01

Add PRT Wechat for consultation

Share this page

Exhibitor E-invitation

Invitation / Product Poster

AUTOMATIC FLAT-BED DIE CUTTING AND FOIL STAMPING MACHINE

The automatic flat-bed die cutting and foil stamping machine is a new generation of automatic flat-bed die-cutting hot stamping machine, which has been designed and innovatively developed by our company after many years of developing automatic flat-bed die-cutting hot stamping machine. It is mainly used for die-cutting, bronzing, indentation and cold pressing of paper boxes, cartons and trademarks in the packaging and decoration industry, especially for various high-level and fine prints, such as cigarette boxes, wine boxes, gift boxes, small appliances boxes, cosmetic boxes, etc., can be used for ordinary bronzing and embossing on this machine to obtain three-dimensional, exquisite and beautiful printed products. This machine realizes automation from paper feeding, die cutting, hot stamping, and paper delivery. It can realize the functions of automatic detection, fault display, and non-stop sampling. It also has the advantages of high die-cutting pressure and high registration accuracy. The main drive system of the machine is equipped with a pneumatic

clutch and a braking device; the main sprocket shaft is equipped with a torque limiter (safety clutch); and multiple safety detection electric eyes and safety devices, etc.; can avoid the operation due to emergencies to the greatest extent The injury and equipment damage caused by the operator shall fully protect the safety of persons and equipment.

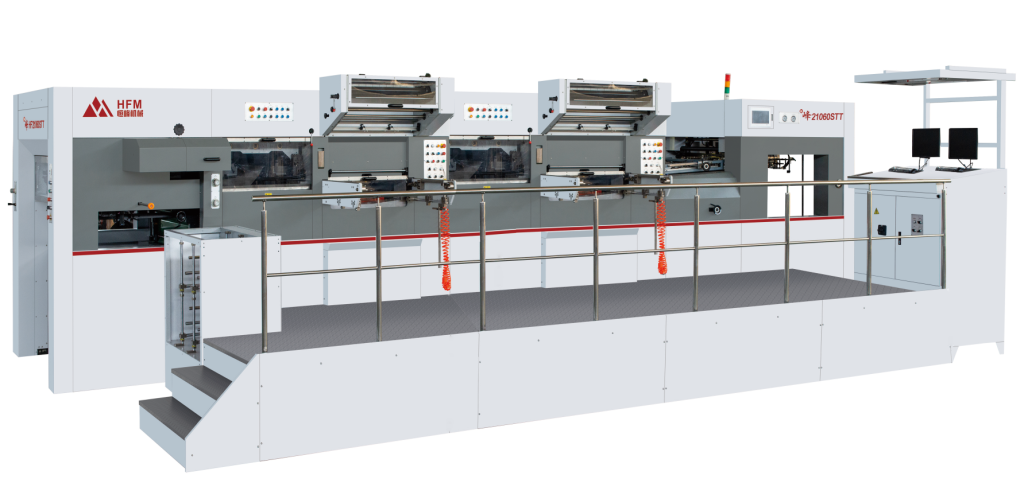

AUTOMATIC HIGH SPEED DOUBLE STATION HOT FOIL STAMPING & DIE CUTTING MACHINE WITH STRIPPING

South China first show

The job you can realize in one pass as below:

.1. hot stamping+hot stamping

.2. hot stamping+deep embossing

.3. hot stamping+die cutting

.4. deep embossing+deep embossing

5.deep embossing+die cutting

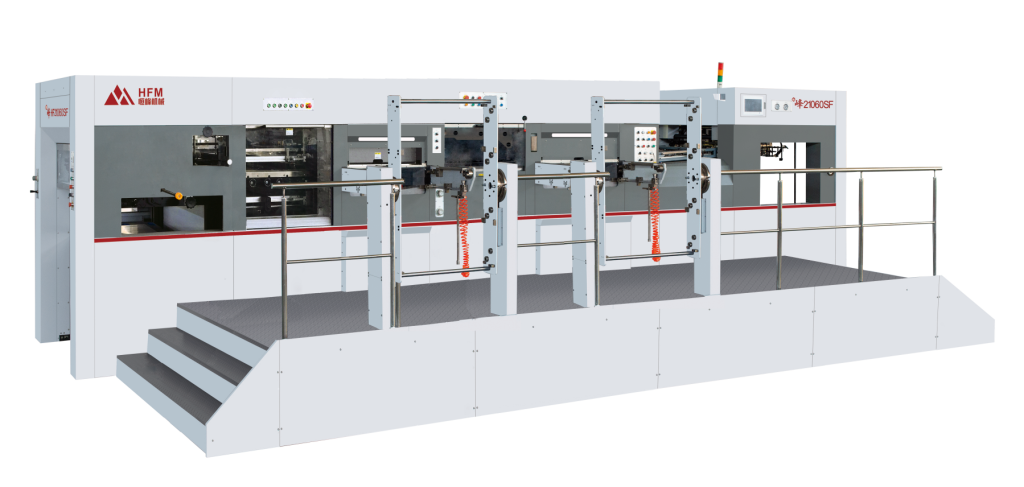

AUTOMATIC HIGH SPEED STAMPING DOUBEL STATION AND DIE CUTTING MACHINE WITH STRIPPING

South China first show

The job you can realize in one pass as below:

.1. die cutting+die cutting+Stripping

.2. deep embossing+deep embossing

3. deep embossing+die cutting+Stripping

思源黑体预加载(勿删): TANGSHAN HENGFENG MACHINERY MANUFACTURE CO., LTD.